Custom Labels for Small Business Made Simple

Share

Ever wonder how some small brands manage to look so polished and professional right out of the gate? It's often the little things that make the biggest difference, and one of the most powerful tools in their arsenal is a great custom label. Think of it as your brand's first handshake—a silent salesperson that kicks off an unboxing experience customers won't forget.

Why Custom Labels Are a Game-Changer for Your Brand

Investing in high-quality, custom labels is one of the smartest moves a small business can make. It's about more than just slapping your name on a package; it’s about instantly communicating quality and building a real brand identity. A well-designed label tells your story in a single glance, turning what could look like a hobby into a serious, professional venture.

That first impression is everything. Imagine seeing a jar of artisanal jam with a handwritten label. It's charming, sure, but it feels like a farmer's market find. Now, picture that same jar with a professionally printed, beautifully designed label. Suddenly, it’s a premium product you’d expect to see in a gourmet shop. That simple shift in perception can make all the difference in sales and customer trust.

Building Lasting Trust and Recognition

When it comes to building a brand people remember, consistency is key. Using the same fonts, colors, and logo across all your products creates a cohesive identity that customers quickly learn to recognize and trust. Custom labels are a core piece of this puzzle, making your entire product line look intentional and unified.

This visual harmony is what helps you cut through the noise in a crowded marketplace. When a customer spots your product on a shelf or online, you want them to immediately connect it with the great experience they had before. That’s how you turn a one-time buyer into a loyal fan.

Your label isn't just a piece of paper; it's a powerful marketing tool that works for you 24/7, building brand equity with every single view.

The demand for personalized branding is exploding. The personalized stickers market, which is a close cousin to custom labels, hit a valuation of USD 4.58 billion in 2024 and is expected to soar to USD 7.99 billion by 2034. With nearly 60% of consumers saying they prefer customized products, it’s clear that unique branding is what people want.

When you create a memorable label, you’re doing more than just packaging a product—you're crafting an experience. For a deeper look at this, check out our guide on how custom stickers can elevate your small business.

Selecting the Right Label Material and Finish

The way your label feels in a customer's hand says as much about your brand as the design itself. Choosing the right material isn't just an aesthetic decision; it's about making sure your label can do its job and create a memorable experience. Let's dig into the world of materials and finishes to find that perfect match for your product.

Think about where your product will live. This is honestly the most important factor. If you’re selling bath bombs, for example, you absolutely need a label that can survive a steamy, humid bathroom. In that scenario, a waterproof vinyl—often called BOPP (Biaxially Oriented Polypropylene)—is a must-have. It shrugs off moisture, oil, and fading, keeping your brand looking sharp.

Now, flip that scenario. Imagine you're selling organic dog treats in cute, rustic paper bags. A glossy plastic label would feel completely out of place, right? But a textured kraft paper label? That aligns perfectly with an earthy, natural brand identity, adding an authentic touch that plastic just can't match.

Matching Material to Your Product

Getting familiar with the strengths of each material will help you choose with confidence. While the options can seem endless, most small businesses find their sweet spot with one of a few popular choices.

Here’s how I often see it break down:

- For durability and water resistance: White vinyl (BOPP) is the undisputed champion. It’s the go-to for cosmetics, refrigerated foods, and anything else that might get wet. It also provides a crisp, clean canvas for bright, vibrant colors.

- For an eco-friendly, rustic vibe: Kraft paper is your best friend. Its natural, textured feel is perfect for organic products, handmade crafts, and artisanal foods. It sends an immediate message about your commitment to natural ingredients.

- For a classic, cost-effective option: Standard paper labels are great for dry goods, like candles or boxed items, or any product that won’t face moisture.

For really heavy-duty industrial needs, some businesses might look into specialized options like durable Traffolyte labels. But for most of us selling directly to consumers, the real goal is finding that perfect balance between beautiful looks and practical function.

The secret is choosing a material that not only looks incredible on the shelf but also performs flawlessly all the way to your customer's home, protecting your brand's reputation every step of the way.

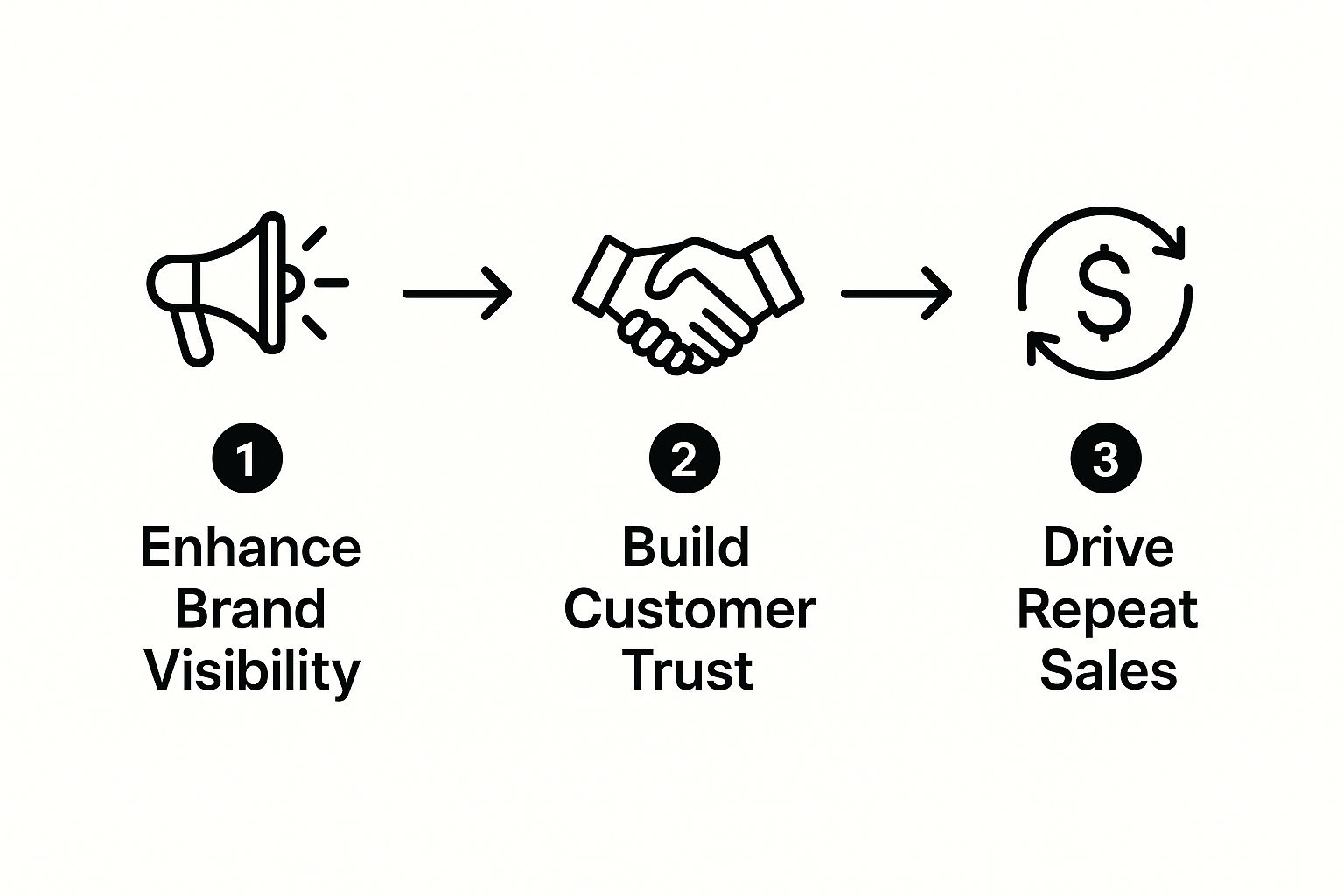

The right material is the foundation of your label strategy. This infographic breaks down how a well-thought-out label can become a powerful tool for growing your business.

As you can see, a great label boosts visibility, which builds the trust you need to earn repeat sales. It’s a powerful cycle that all starts with picking the right paper or vinyl.

A Quick Guide to Common Label Materials

Feeling a little overwhelmed by the choices? This little comparison chart should help you narrow it down based on what your product truly needs.

| Material | Best For | Key Features | Finish Options |

|---|---|---|---|

| White Vinyl (BOPP) | Cosmetics, beverages, food jars | Waterproof, oil-resistant, durable | Glossy, Matte, Soft-Touch |

| Kraft Paper | Organic goods, handmade items | Natural, textured, eco-friendly feel | Uncoated/Matte |

| Standard Paper | Dry goods, boxes, candles | Cost-effective, classic look | Glossy, Matte |

| Clear Vinyl (BOPP) | Glass/plastic containers | "No-label" look, waterproof | Glossy, Matte |

This isn't an exhaustive list, but it covers the most common and effective materials you'll encounter. Think of this as your starting point for finding a material that complements your product's story.

The Final Touch with Finishes

Once you've landed on a material, the finish is what really makes it sing. This final layer not only protects the ink from scuffs and scratches but also sets the final mood for your packaging.

- Glossy: This finish is all about shine and pop. It makes colors look incredibly vibrant and grabs your eye from across the room. It’s also super easy to wipe clean, which is a nice bonus.

- Matte: For a more modern and sophisticated vibe, you can't beat a matte finish. It has zero glare and gives your label a soft, elegant feel that works beautifully for premium or minimalist brands.

- Soft-Touch: This one is pure luxury. It feels velvety and smooth, instantly making your product feel more valuable. It’s that unforgettable little detail that makes customers take notice of high-end items.

Nailing the right material and finish combination is a huge step in creating effective product labels. It ensures your packaging isn't just a box or a jar—it's a critical piece of your brand's story.

Designing Labels That Tell Your Brand Story

Think of your label as more than just a sticker. It's your product's first handshake, its opening line, and its business card all rolled into one. This is your prime opportunity to grab a customer's attention and make them feel something about your brand before they've even tried what's inside.

We all do it—we judge a book by its cover, and we absolutely judge a product by its label. The real goal here is to create something that not only looks fantastic but also feels genuine. If you run a minimalist skincare line, your label should whisper that. If you're a vibrant, playful candle company, it should shout it from the rooftops.

Don't let the design process scare you. With some amazing tools at our fingertips and a few key design principles under your belt, you can craft a label that makes your small business look like a big deal.

Creating a Clear Visual Hierarchy

When someone picks up your product, their eyes need a roadmap. That’s what visual hierarchy is all about—it’s the secret sauce that guides a person’s gaze and prevents your label from looking like a cluttered mess. Your most important information, which is almost always your logo or the product's name, needs to be the star of the show.

Here are a few simple ways to make that happen:

- Size: The easiest trick in the book. Make your logo or product name physically larger than everything else.

- Color: A pop of a contrasting or bold color will naturally draw the eye right where you want it.

- Placement: We read top-to-bottom. Placing your most critical element at the top or dead center gives it immediate importance.

A good rule of thumb I always follow: a customer should be able to identify your brand and what the product is within three seconds. All the other stuff, like ingredients, net weight, or directions, is supporting cast. It can be smaller and take a backseat.

Choosing Your Colors and Fonts Wisely

Color is a language all its own. The palette you choose can trigger specific emotions and immediately start telling your brand's story. Think about it—greens and browns feel earthy and organic, perfect for natural soaps, while a burst of bright, saturated colors can scream fun and energy. Research has even found that the right color can boost brand recognition by a whopping 80%, so it’s definitely not a detail to gloss over.

Your font choice does the same thing. A clean, modern sans-serif font like Montserrat can give off a sleek, professional vibe. On the other hand, a classic serif font like Garamond can feel more traditional and trustworthy. But above all else, the golden rule is readability. If a customer has to squint to read your label, you've already lost them. I always recommend sticking to two, maybe three, fonts at most to keep the design feeling cohesive and uncluttered.

Your label's design isn't just about looking pretty. It's about strategic communication that guides the customer's eye, evokes emotion, and builds an immediate sense of trust in your brand.

Putting It All Together

Okay, you’ve got your hierarchy, your colors, and your fonts picked out. Now it's time to assemble the puzzle. The name of the game is balance. You need to fit your logo, product name, and all the essential info onto a small space without it feeling crowded.

My best advice? Don't be afraid of white space! That negative space is your friend. It gives all the other elements room to breathe and instantly makes the entire design look more polished and easier to digest.

If you’re ready to get hands-on, user-friendly tools like Canva have made great design accessible to everyone. For those who want something truly one-of-a-kind without starting from scratch, exploring a collection of professionally designed customizable stickers can be a fantastic source of inspiration or even a ready-made solution that perfectly captures your brand's unique personality.

Getting Your Design File Ready for the Printer

You’ve poured your heart into creating a fantastic label design. Now comes the final, crucial step: prepping the file for printing. Think of it as the technical handshake between your computer screen and the printing press. Getting these details right is the difference between getting the exact labels you envisioned and facing a frustrating, costly reprint.

First up, let's talk color. Your monitor glows with light, creating colors using an RGB (Red, Green, Blue) model. But printers don't use light; they use ink. They mix physical pigments in CMYK (Cyan, Magenta, Yellow, Black) to create colors on paper. If you send an RGB file to a printer, its software has to guess how to translate those colors, and the results can be... disappointing. Vibrant blues can turn purple, and bright reds might look muddy. To avoid this, always convert your design to the CMYK color mode yourself. It’s the single best way to ensure what you see is what you get.

Don't Forget the Margins

To get that crisp, professional look, printers need a little wiggle room around the edges of your design. This involves three simple but super important concepts.

- Bleed: This is for any color or image that touches the very edge of your label. You need to extend that design element slightly beyond the actual cut line. This creates a buffer, so if the cutting blade is off by even a hair, you won't see any weird white slivers on the final product.

- Trim Line: This is exactly what it sounds like—the line where the printer will cut your label to its final size. Everything outside of this gets chopped.

- Safety Margin: This is a quiet zone just inside the trim line. Keep all your crucial elements, like your logo and text, within this area. This guarantees nothing important gets accidentally sliced off during the final trim.

Here’s an easy way to think about it: The trim line is your fence line. The bleed is the bit of lawn you mow on the other side just to be safe. The safety margin is where you place your prized garden gnomes so the lawnmower never gets too close.

Choosing the Best File Format

The type of file you send to your printer matters just as much as the design itself. When it comes to logos, text, or any graphics that need to be razor-sharp, vector files are king.

Vector files, which have endings like .AI, .EPS, or .SVG, are built with math—lines and curves that can be scaled infinitely without losing quality. You could blow up a vector logo from the size of a stamp to the size of a bus, and it would still be perfectly crisp. Raster files like .JPG or .PNG, on the other hand, are made of tiny squares called pixels. Stretch them too much, and you get that blurry, pixelated mess we all want to avoid.

Whenever possible, send your final artwork as a high-quality vector file or a high-resolution PDF. This is especially true if you’re getting creative with shapes, like with custom-shaped die-cut stickers that require precise vector paths for the cutting machine to follow.

It also doesn't hurt to have a basic grasp of how things are actually made. Taking five minutes to understand the key differences between digital vs. offset printing can clue you in on why certain choices about color or order size might matter more than you think.

Using Variable Data to Personalize Your Labels

Ready for a pro move that can seriously set your brand apart? Let's talk about variable data printing, or VDP. This is a fantastic technique that lets you change up elements—like text, numbers, or even graphics—on each and every label, all within the same print run. It might sound like something only the big guys can do, but it’s more accessible for small businesses than you'd think.

For instance, if you're a local coffee roaster, imagine printing a unique "roasted on" date on every bag. That simple detail screams freshness and quality to your customers. Or, if you make small-batch candles, you could add a specific batch number to each one. It's a small touch that adds a layer of authenticity and makes quality control a breeze.

This kind of detail isn't just about branding anymore; it’s about creating a hyper-personalized experience that can build some serious customer loyalty.

Putting Personalization into Practice

The creative possibilities with VDP are pretty much endless. It’s a powerful tool for making each customer feel like they’re getting something made just for them.

Here are a few real-world ideas to get your gears turning:

- Wedding Favors: If you make event favors, you could print each guest's name right on the label. It instantly transforms a simple gift into a cherished keepsake.

- Contests and Promotions: Slap a unique QR code on each label. When scanned, it could take customers to a contest entry form or unlock a special discount on their next order.

- Numbered Editions: Do you sell limited-run products, like a seasonal hot sauce or a special art print? VDP makes it easy to number each item (e.g., "No. 12 of 100"). This creates a feeling of scarcity and exclusivity that collectors absolutely love.

By personalizing your labels with variable data, you're not just selling a product; you're creating a unique interaction with each customer, making your brand more memorable and valuable.

And this isn't just some niche trick. The global variable data printing labels market was valued at a whopping USD 16.64 billion in 2023 and is only getting bigger. A huge driver for this growth is the boom in e-commerce, where personalized packaging helps small online shops create a real, tangible connection with their customers. You can explore more about this growing market to see just how much it's shaping the retail world.

How to Get Started with VDP

So, how do you actually make this happen? It’s simpler than it sounds. Most professional printers that offer custom labels for small business are well-equipped to handle VDP jobs.

The process boils down to two key things you'll need to provide:

- A static design template: This is your main label design—the part that doesn't change. It includes your logo, brand colors, and all the standard information.

- A data file: This is usually just a simple spreadsheet, like an Excel file. Each row in the spreadsheet contains the unique info for a single label. Think of a column for "Batch Number," "Customer Name," or "Unique Code."

You send both of these files over to your printer. Their specialized software then merges the two, seamlessly creating hundreds or thousands of one-of-a-kind labels in a single pass. This makes personalization scalable and surprisingly affordable, even for the smallest brands.

Your Custom Label Questions, Answered

Diving into custom labels for the first time can feel like a lot. As a small business owner, you're already wearing a dozen different hats, and navigating the world of printing specs and legal requirements can seem like one more thing to add to an overflowing plate.

We get it. That's why we've pulled together the most common questions we hear from entrepreneurs just like you. Think of this as your go-to guide for those practical details that make all the difference.

What's the Smallest Order I Can Place?

This is easily the number one question, and for a good reason—every dollar counts when you're growing a business. The good news is that the days of needing to order thousands of labels are long gone. Thanks to modern digital printing, many printers now offer incredibly low minimum order quantities (MOQs). You can often find options to print as few as 50 or 100 labels.

This is a huge advantage for small businesses. It means you can affordably test a new product, create a limited edition seasonal item, or just get started without a massive upfront investment. Always ask about the MOQ right away; it’s a crucial factor in finding a printer that fits your business needs.

How Quickly Will I Get My Labels?

When you’ve got products ready to go, waiting on labels can be frustrating. So, what’s a realistic timeline? Generally, you can expect your labels to ship within 5-10 business days after you’ve signed off on the final design proof.

Keep in mind that a few things can affect this timeline:

- Design Complexity: A standard square or circle label is quicker to produce than one with an intricate, custom die-cut shape and special finishes.

- The Printer's Schedule: Things can get a little busier during peak seasons, like the holiday rush, which might add a day or two to the turnaround.

- Your Proof Approval: The production clock officially starts ticking the moment you give your final "yes!" to the proof. The faster you review it, the faster you get your labels.

What Has to Be on My Label?

Beyond your gorgeous logo and branding, some products have to follow strict legal guidelines. This is especially true if you’re in the food, beverage, cosmetic, or wellness space. While the rules change depending on your product and location, some common must-haves include net weight, a full ingredient list, and your business contact information.

It’s ultimately your responsibility to make sure your labels are compliant with all local and federal regulations. The Fair Packaging and Labeling Act is an excellent place to start, but you should always research the specific rules for your industry.

Getting your labeling right isn't just about good marketing; it's about building trust and ensuring customer safety. Taking the time to double-check compliance is one of the most professional things you can do for your brand.

This need for accuracy is a huge driver behind the global labeling services market, which was valued at USD 5.75 billion in 2024 and is expected to more than double by 2034. The food and beverage industry, in particular, is pushing this growth as consumers demand total transparency. You can discover more insights about labeling market trends to see just how vital clear information has become.

At everone prints, we believe getting professional labels shouldn't be complicated. We want you to focus on what you do best—creating incredible products. Ready to bring your brand’s vision to life? Start designing your custom labels today!