How to Make Custom Stickers From Scratch

Share

Ever wondered how to turn that cool idea in your head into a real, hold-in-your-hand sticker? It's actually a pretty fun and straightforward process. At its core, you just need to nail down your design, pick the right material for the job (like sturdy vinyl or classic paper), and then let a pro printing service like Everone Prints handle the rest.

This guide is here to walk you through it all, step by step, so you can transform your concepts into awesome, high-quality stickers.

Your Journey to Amazing Custom Stickers Starts Here

So, you've got a killer idea for a sticker but feel a little stuck on where to even start. Don't worry, you're in the right place. Making your own custom stickers has never been easier, whether you're a small business owner looking for fresh branding, an artist ready to share your work, or just someone who loves adding a personal touch to their stuff.

Think of this guide as your creative co-pilot. We'll navigate the entire journey together, from that first spark of an idea to the moment you peel and stick your finished product. With a partner like Everone Prints, you can leave the technical heavy lifting to us and focus on what you do best: creating.

A Quick Peek at Your Sticker-Making Adventure

The whole process really boils down to a few key phases. Getting familiar with them from the get-go helps make the entire project feel less daunting and a lot more fun.

Here's what you can expect:

- The Creative Spark: This is where it all begins. You’ll take your idea and shape it into a print-ready digital file.

- Choosing Your Vibe: Next, you'll pick the perfect material and finish. Think durable, weatherproof vinyl for a car bumper or a sleek matte paper for elegant product labels.

- The Magic of Printing: Your design gets professionally printed and precision-cut, ensuring every detail looks fantastic.

- The Grand Finale: The best part! Applying your brand-new sticker and seeing it out in the world.

People love unique, personal touches, and the numbers back it up. The global market for personalized stickers is on track to hit an incredible USD 7.99 billion by 2034, with an annual growth rate of about 5.73%. It just goes to show how much impact a simple sticker can have. You can dig into the full report on towardspackaging.com.

Key Takeaway: The secret to a great sticker is a solid plan. Once you get a handle on the main stages—design, material selection, printing, and application—you'll be all set to create something truly special.

For entrepreneurs, stickers are an incredibly effective marketing tool. To get more ideas, dive into our guide on using custom stickers for your small business.

Custom Sticker Creation At-a-Glance

To give you a bird's-eye view, here’s a quick summary of the key stages involved in making your own custom stickers from start to finish.

| Stage | Key Objective | Tools & Services |

|---|---|---|

| Design & Concept | Convert your idea into a digital, print-ready file. | Adobe Illustrator, Canva, Procreate |

| Material Selection | Choose the right material and finish for your needs. | Everone Prints' material options |

| Printing & Production | Professionally print and cut your sticker design. | Everone Prints' printing services |

| Application | Apply the finished sticker to a surface. | A clean surface and a steady hand! |

Following these stages will help keep your project on track and ensure you end up with a sticker you'll be proud to show off.

Bringing Your Sticker Design to Life

The heart and soul of any great sticker is the design. This is the fun part, where your idea finally jumps from your brain onto the screen, getting ready to become a real, tangible thing. It's all about picking the right tools and getting a handle on a few key concepts to make sure your sticker looks just as awesome in your hand as it does on your monitor.

You don't have to be a seasoned graphic designer to make something incredible. Whether you’re cooking up a slick logo for your brand or a quirky illustration for your water bottle, the software you choose can really set you up for success. And don't worry, there are fantastic options out there for every skill level and budget.

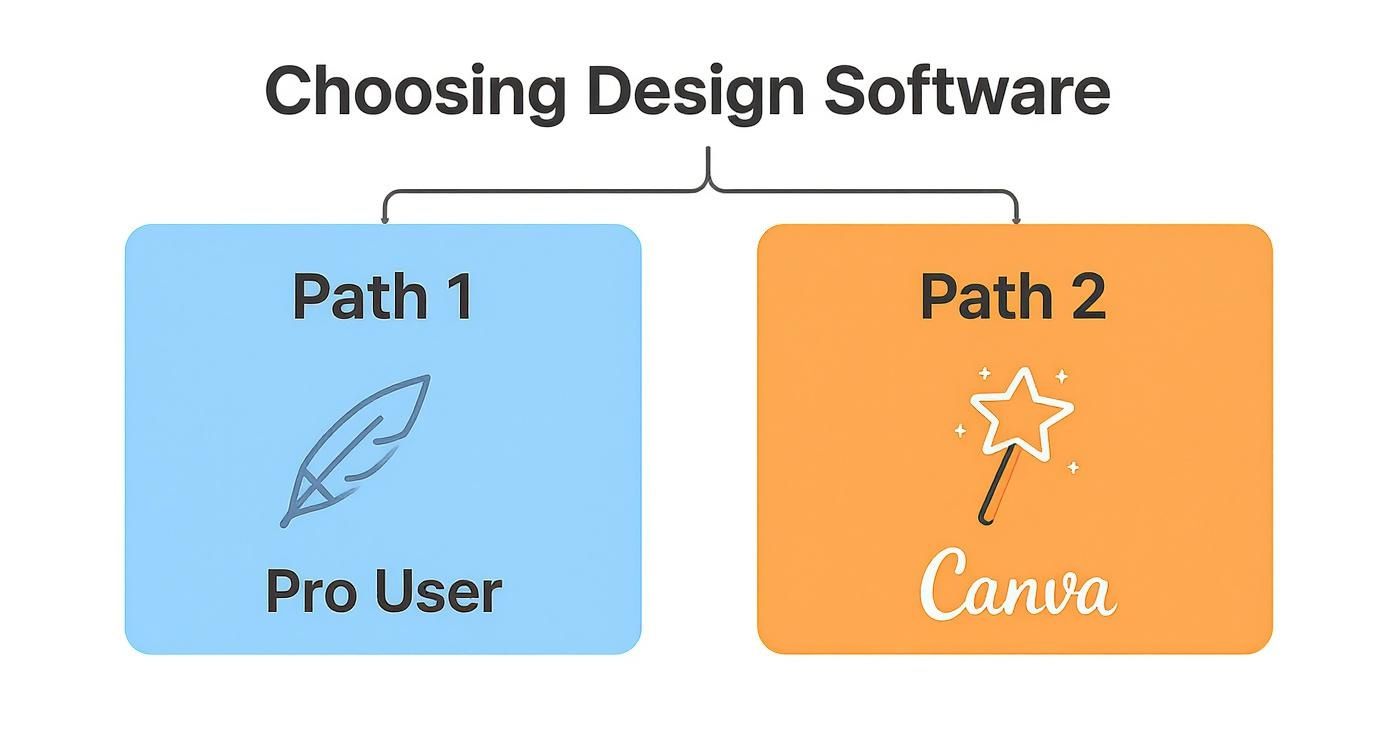

Choosing Your Design Playground

If you're looking for total creative control and professional polish, the industry gold standard is Adobe Illustrator. It’s an absolute beast for creating vector graphics—these are designs built with mathematical lines and curves, not pixels. The magic of vectors is that you can blow your design up to the size of a bus or shrink it down to fit on a keychain, and it will stay perfectly crisp.

But you absolutely don't need to splurge on fancy software to get a beautiful result. Free and incredibly easy-to-use platforms like Canva have totally leveled the playing field. They give you a huge library of templates, fonts, and graphics that make designing feel less like work and more like play.

Tools like Canva have intuitive drag-and-drop interfaces, so you can jump right in and start creating without getting bogged down by a steep learning curve. It’s all about getting your ideas out there quickly and easily.

Pro Tip: If you're working with photos or any art made of pixels (these are called raster images), always design at a high resolution. I always recommend 300 DPI (dots per inch) at the actual size you want the sticker to be. This is your best defense against a blurry, pixelated final product.

Prepping Your File for Flawless Printing

Okay, so your masterpiece is finished. Now what? A few quick technical checks will ensure it prints perfectly. Think of these steps as the bridge between your digital file and a vibrant, perfectly cut physical sticker.

First up is color. Your computer screen shows colors in RGB (Red, Green, Blue), which is perfect for digital displays. Printers, on the other hand, mix inks using CMYK (Cyan, Magenta, Yellow, Black). Taking a moment to convert your file to CMYK helps ensure the colors you fell in love with on-screen are what actually come out of the printer.

Next, you'll want to add a bleed. This is simply a small border of your design that extends past the final cut line.

- What it is: It’s a safety margin, usually around 0.125 inches, that surrounds your artwork.

- Why it's important: It's insurance against tiny shifts in the cutting machine. Without it, you might get a frustrating sliver of white along the edge of your sticker.

- How it works: Just extend your background color or pattern into this bleed area. That way, if the cut is a hair off, it slices through your design instead of blank paper, giving you a clean, professional look.

When you're in the design phase, you might be weighing whether to start from scratch or use a template. Thinking about custom graphics development can help you decide which path is right for your project.

A lot of these core design principles carry over to other printed goods, too. If you want to go a bit deeper, have a look at our guide on how to create custom labels, which covers similar ground. Honestly, getting your file prep right is the single best thing you can do to guarantee you’ll be thrilled with the final result.

Choosing Materials That Tell Your Story

Alright, you've nailed the design, and it's looking sharp. Now for the fun part: deciding what your sticker will actually feel like. This isn't just a minor detail; the material you pick is the canvas for your art. It’s what makes your sticker feel cheap or premium, flimsy or tough.

Think about where this sticker is going to live. A sticker for a rugged Nalgene bottle needs a totally different superpower than one you're using to seal a customer's order. Getting this right means your stickers won't just look amazing on day one—they'll stay that way.

Durable Vinyl for Life's Adventures

If your stickers are heading into the wild (or just a really chaotic backpack), you can't go wrong with durable vinyl. This stuff is the undisputed champion of toughness, making it a no-brainer for anything that gets handled a lot or faces the great outdoors.

I'm talking about things like:

- Car Decals: You need something that can laugh in the face of sun, rain, and the occasional high-pressure car wash.

- Laptops & Water Bottles: These are high-traffic areas. Vinyl holds up against bumps, scuffs, and spills, keeping your design looking fresh.

- Skateboards & Coolers: For gear that takes a beating, vinyl's got your back. It sticks tight and shrugs off scratches.

At Everone Prints, we use a seriously high-quality vinyl that keeps your colors bright and your sticker locked in place. It's built to last.

This whole process, from design software to material choice, is about finding the right fit for your project and skill level.

Just like there's a perfect tool for every designer, there's a perfect material for every sticker.

Classic Paper and Eye-Catching Finishes

While vinyl is the workhorse, sometimes you need something with a more classic touch. Paper stickers are fantastic for indoor applications where you don't need that heavy-duty weatherproofing. They're perfect for adding a branded touch to packaging, sprucing up a journal, or for one-off event giveaways. The texture of paper can give off a subtle, organic vibe that vinyl just can't match.

If you're curious about how different paper types can affect a design, our guide on the best paper for photo printing has some great insights that apply here, too.

But the base material is only half the story. The finish is what really dials in the personality.

My Two Cents: Don't underestimate the power of a finish. A glossy coat will make your colors scream with energy, while a matte finish gives you a cool, modern look with zero glare. It completely changes the mood.

Want to go from "nice sticker" to "whoa, where did you get that?" Specialty finishes are your ticket.

A holographic finish catches the light and creates this incredible rainbow effect that's impossible to ignore. Or, for something a bit more fun and luxe, a glitter finish adds actual sparkle. It’s details like these that are fueling the custom sticker craze. The custom die-cut sticker market hit an impressive USD 66 million in 2025 precisely because these unique options allow for such killer branding.

Making sense of all these choices can be tricky, so let's break it down in a simple table.

Sticker Material and Finish Comparison

| Material/Finish | Best For | Durability | Visual Appeal |

|---|---|---|---|

| Durable Vinyl | Outdoor use, water bottles, cars, laptops | High (waterproof & scratch-resistant) | Smooth, professional, vibrant colors |

| Matte Finish | Sophisticated branding, art prints | Varies with base material | Soft, non-glare, modern & subtle |

| Glossy Finish | Bold, colorful designs, product labels | Adds a layer of protection | High-shine, makes colors pop, vibrant |

| Paper | Indoor use, packaging, journals, crafts | Low (not water-resistant) | Classic, organic, textured feel |

| Holographic | Eye-catching logos, limited editions | High (usually on a vinyl base) | Shimmering, rainbow-like, dynamic |

| Glitter | Fun, celebratory, or glamorous designs | High (usually on a vinyl base) | Sparkly, textured, attention-grabbing |

Ultimately, the best choice is the one that aligns with your brand's personality and the sticker's purpose. Whether it's tough-as-nails vinyl or a dazzling glitter finish, the right material will make your design truly unforgettable.

How Your Stickers Come to Life

https://www.youtube.com/embed/GlecDUdZdkE

You’ve nailed the design and picked the perfect material. Now for the fun part: watching your idea become a real, tangible thing you can hold. This is where we work our magic at Everone Prints, turning that digital file on your screen into a stack of vibrant, perfectly cut stickers. Knowing a bit about what happens behind the scenes can give you a lot of confidence in the final product.

Once your artwork is uploaded, our team gives it a quick once-over to make sure it's ready for the big leagues. From there, we fire up our high-end, color-calibrated printers and lay your designs down on massive sheets of the material you chose.

Getting the Perfect Cut

After the ink is dry, it’s time to cut. How a sticker is cut completely changes its look and feel. The two big players in the custom sticker world are die-cut and kiss-cut, and picking the right one is all about the effect you're going for.

A die-cut sticker is cut straight through both the vinyl and the paper backing, following the exact outline of your design. The result is a clean, custom-shaped sticker with no extra backing material around the edges. It’s a premium look that really stands out.

A kiss-cut sticker, on the other hand, is only cut through the vinyl layer. The paper backing stays intact, usually as a square or rectangle. This makes the sticker super easy to peel and keeps any delicate parts of your design protected until you’re ready to stick it.

The Main Difference: Think of it like this—a die-cut sticker is the shape of your design, while a kiss-cut sticker has the shape of your design on a larger backing. Both are great choices; it really just boils down to your personal preference and how you plan to use them.

What to Expect After You Order

Let's walk through a real-world example. Say you just uploaded an awesome new logo for your coffee shop. Here’s what happens next:

- File Check: You send your design file through the Everone Prints portal. Our pre-press team (and our automated system) will immediately scan it for any red flags, like low-resolution images or missing bleed areas.

- Your Digital Proof: Before a single drop of ink is used, we’ll send you a digital proof. This is your final preview that shows precisely how your sticker will look, complete with the final cut lines.

- The Final Go-Ahead: This is your moment to give us the green light. If it all looks perfect, you approve the proof, and your order heads straight into the production queue. Need a little tweak? No problem. Just let us know.

This proofing step is our built-in safety net. It’s there to make sure you know exactly what you’re getting, guaranteeing you’ll be thrilled with the final result.

The way custom stickers are made has really changed the game for modern marketing. If you want to get into the nitty-gritty, learning about the differences between digital and offset printing methods is a great place to start. This accessibility is what makes them such a powerful tool. In fact, 72% of businesses now see custom stickers as a seriously cost-effective way to build their brand and connect with customers.

Want to see this popular style in action? Take a peek at our collection of custom die-cut stickers to get a better feel for the final product. This little peek behind the curtain should give you peace of mind that you'll get a flawless, professional result every single time.

Applying Your Stickers for a Perfect Finish

The moment of truth has arrived—your box of custom stickers from Everone Prints is in your hands, and they look incredible. But the job isn't done yet. The final step is getting them onto their new home, and doing it right is what turns a great sticker into a perfect one.

Don't rush this part. A few minutes of prep can make all the difference, saving you from the frustration of crooked placement, trapped dust, or those dreaded air bubbles. Let's make sure all your design effort pays off.

Prep Your Surface for Success

Think of the surface as your canvas. If it's covered in dust, fingerprints, or grime, even the stickiest sticker will have trouble holding on. A quick clean is honestly the most important thing you can do for a long-lasting application.

For smooth, non-porous surfaces like glass, metal, or plastic, it's super simple.

- The Best Tool: Grab some isopropyl alcohol and a lint-free cloth. It's my go-to because it cuts through grease and evaporates in seconds, leaving a perfectly clean slate.

- Good Alternatives: No alcohol on hand? A standard glass cleaner or even a bit of soap and water works. The key is to make sure the surface is 100% dry before you even think about peeling off the sticker backing. Any moisture is a big no-no.

This one step ensures the adhesive makes a solid bond, keeping your sticker looking sharp for years.

The Best Techniques for a Smooth Application

For smaller stickers, you can usually just eyeball it. I like to peel back just a corner, anchor it to the surface, and then slowly smooth the rest down with my thumb. Working from the center out helps push any air to the edges.

But for larger graphics or designs that need to be perfectly straight, the "hinge method" is a total game-changer. I use this all the time for things like laptop covers or car decals.

- Position It: Figure out exactly where you want the sticker to go, but leave the backing on for now.

- Make a Hinge: Place a strip of masking tape right across the middle of the sticker, fastening it to the surface. This creates a flexible hinge.

- Peel Half: Lift one side of the sticker up toward the hinge and peel the backing paper away from it. Just go up to the tape, then cut that loose piece of backing paper off.

- Squeegee It Down: Now, using a credit card or a squeegee, smooth that exposed, sticky side onto the surface. Start from the tape hinge and work your way outward with firm, overlapping strokes.

- Repeat and Finish: Gently remove the masking tape hinge. Lift the other half of the sticker and repeat the process—peel the remaining backing and squeegee it down.

Insider Tip: If a pesky air bubble shows up despite your best efforts, don't try to peel the sticker back up! Just take the very tip of a craft knife or a pin and poke a tiny hole right in the middle of the bubble. You can then easily press the trapped air out, and the tiny hole will be virtually invisible.

With these tricks up your sleeve, you can apply any sticker with confidence and get that smooth, professional, bubble-free finish every single time.

A Few Common Questions We Get About Making Stickers

It’s totally normal to have a few questions pop up, especially when you're diving into your first sticker project. We get it. Over the years, we've heard just about every question in the book, so we've pulled together the most common ones right here.

Think of this as your quick-reference cheat sheet for those little details that can make a big difference.

All About Your Design Files

So, let's talk about the nitty-gritty of your artwork. This is where a lot of people get stuck, but it's simpler than it sounds.

A question we hear all the time is, "What's the absolute best file format for my sticker design?" Hands down, if you want your stickers to look incredibly sharp, a vector file is the way to go. We're talking about formats like AI, EPS, or SVG. The magic of vector files is that you can scale them up to the size of a billboard or down to a postage stamp without losing a single drop of quality.

But what if you only have a standard image file, like a JPEG or PNG? No problem at all. Just be sure it's saved at 300 DPI (dots per inch) at the exact size you want it printed. This is the gold standard for high-resolution printing, and it’s the key to avoiding any fuzziness or pixelation on the final product.

Then there's the big one: color. "Will the colors on my sticker look exactly like they do on my computer screen?"

- Screen vs. Print: It’s a classic mix-up. Your screen creates color with light (RGB - Red, Green, Blue), while our printers use ink (CMYK - Cyan, Magenta, Yellow, Black). They're two different languages for color.

- The Conversion: We handle the technical side by converting your files to CMYK for printing. The match is usually spot-on, but some super-vibrant, electric colors on your screen might look a little more muted in print. That's just the nature of ink vs. light.

Here's Our Promise: You'll never be in the dark. We send a free digital proof for every single order. This shows you precisely how your design will look post-conversion, complete with cut lines, so you can give it the thumbs-up with 100% confidence before anything goes to print.

Your Order and Our Process

Okay, let's switch gears to the logistics of getting your stickers made.

"Do I really have to order a thousand stickers to start?" Absolutely not! This isn't the 90s. At Everone Prints, our minimum is just 10 custom stickers. This is a game-changer for anyone who wants to test a new design, whip up a small batch for an event, or just make a few for fun.

This low-minimum approach lets you dip your toes in the water without a massive commitment.

Of course, if you are ready to go big, the price per sticker gets better the more you order. It’s a fantastic setup for small businesses and artists looking to stock up on their best-sellers.

Finally, "How fast can I get my hands on them?" We know you're excited, and we move fast. After you approve the final proof, our standard production time is usually just a few days. We take a lot of pride in getting your stickers printed and shipped out the door quickly, without ever cutting corners on quality.

Ready to stop wondering and start creating? Everone Prints strips away all the guesswork. Just upload your design, pick your favorite material, and you'll have a free digital proof back in a few hours. Let's make something awesome together.